Reading specifications for screws can be confusing for beginners, but understanding these details is essential for choosing the correct fastener for any project. Screw size, thread pitch, material grade, and head style all determine how a screw performs. Learning how to interpret these specifications ensures safer installations, better compatibility, and stronger long-term results.

Understanding Screw Diameter and Length

Two of the most important specifications are diameter and length. Diameter affects load-bearing strength, while length determines how deeply the screw penetrates the material. A screw’s diameter is often listed as a gauge number, metric size, or fractional measurement. Length is typically measured from the tip to the point where the head meets the surface. Choosing the right combination is crucial for secure fastening.

Metric vs. Imperial Sizing Systems

Screws are classified using two sizing systems: metric (e.g., M4, M6) and imperial (e.g., #8, 1/4”). Metric sizes represent screw diameter in millimeters, while imperial systems use gauge numbers or fractional inches. Understanding both systems helps users select screws compatible with existing holes or fittings, especially in international or mixed-standard projects.

Thread Pitch and Thread Count

Thread pitch refers to the distance between threads in metric screws, while thread count (TPI—threads per inch) is used for imperial screws. Fine threads have smaller pitch or higher TPI and provide better strength in metal applications. Coarse threads have larger pitch and are ideal for wood or soft materials. Matching thread type to material ensures proper engagement and prevents stripping.

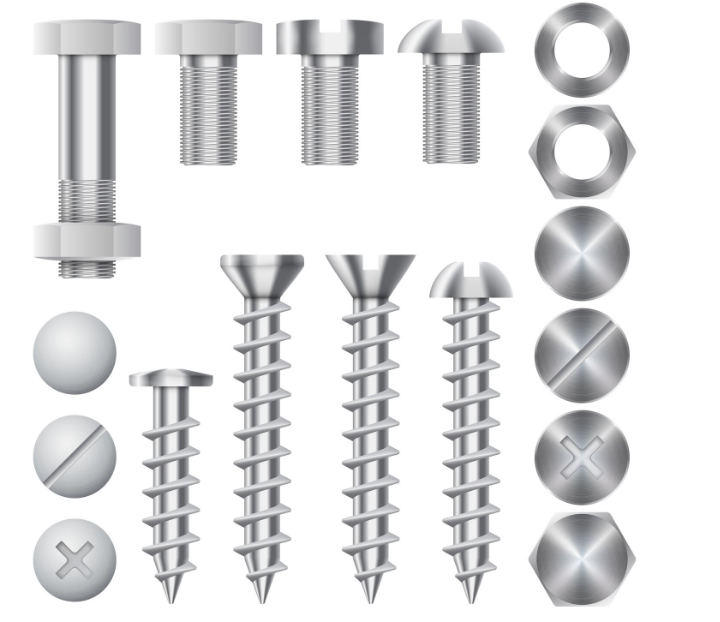

Drive Type and Head Style Indicators

Screw specifications often include abbreviations for head shape (e.g., FH for flat head, PH for pan head) and drive type (e.g., T25 for Torx, PH2 for Phillips). These indicators help users choose the correct driver bit and ensure compatibility during installation. The right head style improves load distribution, while the correct drive prevents slipping and cam-out.

Material Grades and Strength Ratings

Material grade descriptions indicate a screw’s durability, strength, and corrosion resistance. For example, stainless steel grades such as 304 or 316 show levels of corrosion protection, with 316 offering superior marine resistance. Hardened steel screws may list grade numbers showing tensile strength. Understanding these grades helps users select fasteners suitable for structural, outdoor, or high-stress applications.

Coating and Finish Labels

Specifications may also include information about coatings such as zinc plating, hot-dipped galvanization, black oxide, or ceramic layers. These coatings protect screws from rust and improve performance in harsh environments. Choosing screws with the right coating increases lifespan and reduces maintenance in both indoor and outdoor projects.

Point Types and Their Purpose

Screw points—such as sharp, self-tapping, or self-drilling tips—are included in specifications to indicate how the screw should be used. Sharp points are best for wood, while self-tapping and self-drilling points excel in metal applications. Point type affects installation speed, required tools, and suitability for specific materials.

How to Match Specifications to Your Project

Matching screw specifications to your project ensures reliable fastening. Consider the material, required torque, environmental exposure, and load-bearing requirements. For structural or outdoor work, choose screws with strong material grades and corrosion-resistant coatings. For detailed woodworking or metalwork, thread type and head style matter more. Proper specification selection prevents failures and improves overall project quality.

Why Understanding Specifications Improves Results

Learning how to read screw specifications allows users to make informed choices instead of guessing. By understanding size, thread type, material grades, and coatings, you can select screws that meet your project's demands with precision and reliability. This knowledge leads to safer installations, stronger connections, and more professional outcomes.